Installing Underlayment

Be sure to click on the videos and pictures below to see a detailed look at the steps it takes to properly dry in a an asphalt shingle roof.

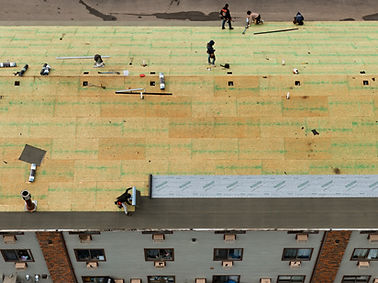

Wheat Suites - Dry In

Wheat Suites - Dry In

Wheat Suites - 10.17.25 - Dry in Vertical

Wheat Suites - 10.17.25 - Ice and Water

Wheat Suites - 10.20.25 - Magnetic Hammer

Wheat Suites - 10.17.25 - Gutter Apron

Rolling out Ice and Water, and Synthetic Felt

Over view of the process of rolling out the Ice and Water (along the eves at the bottom of the roof's run), and also beginning to roll out the synthetic felt (white fabric).

Pinning down Ice and Water

The underside of the Ice and Water has a sticky membrane that adheres directly to the deck. Ice and Water is stapled and nailed on top of the direct stick to the deck.

Final step in rolling out synthetic felt

Making the last run of underlayment, other than the layer that goes over the ridge.

Measuring for chalk line

Properly spaced runs of shingles is essential to maintaining the manufactures' warranty.

Snapping chalk line

Straight lines are essential to creating a water tight seal.

Snapping line in the middle of the run

Takes a whole team to snap straight lines along the run of the roof.

Getting low for perspective

The workers are making sure to keep their chalk lines straight and true.

Lots of cap nails

Click on the picture to expand and see the thousands of cap nails used to secure the underlayment to this roof.

Rolling out Ice and Water along the eves

The worker is getting low to make sure that the ice and water is properly lined up.

Checking new Gutter Apron

Although we aren't replacing the gutters at this point in the process, the workers install new gutter aprons.

Getting rolled out

Another look from above at the team rolling out the ice and water, and synthetic felt.